Overview

Synapse was tasked with creating test fixtures for an upcoming EVT build at a Chinese CM. Units of the wearable electronic device were to be tested after each high risk manufacturing process: FPC fabrication, placement of components including the battery, low pressure molding, and overmolding.

The Challenge

The schedule to have the fixtures designed and tested prior to EVT was aggressive. The circuit board being tested had tiny test points and poor registration features.

The Solution

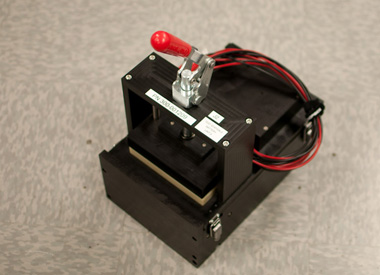

A tolerance analysis study was created to drive the design of the test fixtures. Tight tolerances led to the traditional method of fixture design being abandoned for an approach with a smaller number of items in the tolerance stack. Parts were machined internally and externally. The ICT and contact-less fixtures were built along with their ancillary pieces of test equipment.

My Contributions

- Tolerance analyses between test points and pogo pins

- 3D design in Solidworks

- Packaging for ancillary test equipment

- Machining of simple parts on tight timelines

- Assembly of test fixtures and associated equipment

- Communicated with CM to obtain several iterations of DFM.

|